- Gains of 10bhp and 10lbft

- Temperature drops of up to 20°C

- Reduced turbo lag, increased response

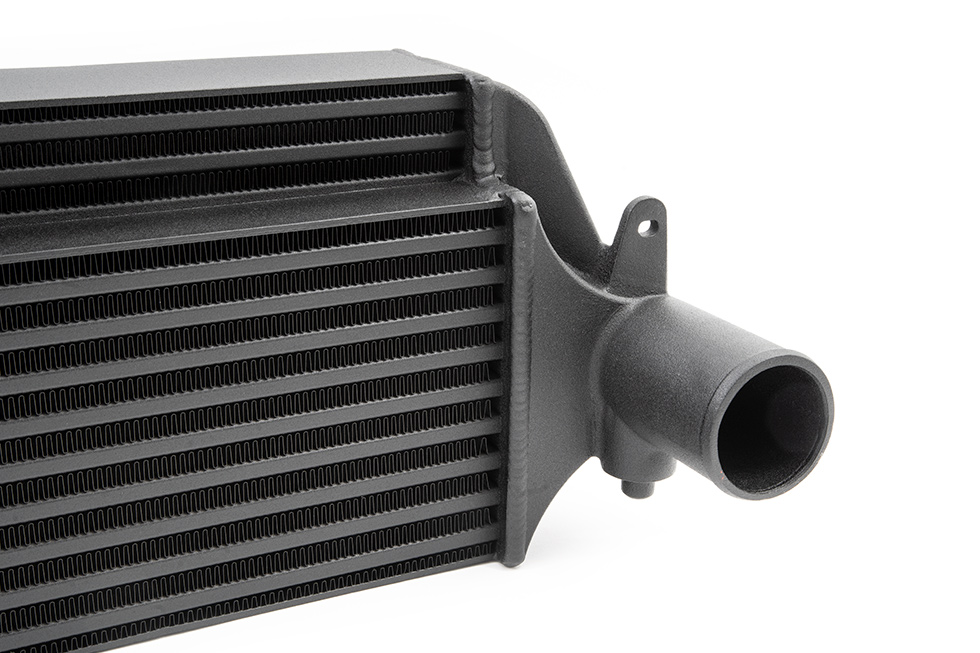

- Greater overall surface area for greater heat dissipation

- Utilising a race specification tube and fin construction air core

- High flow cast end tanks ensuring optimum air transition for cooling efficiency

- Dyno proven horsepower and torque gains

- A smoother power curve

- Volumetric increase of more than 100%, without additional lag

- Frontal area increase of over 40%

- Includes necessary hardware and instructions for installation

- Lifetime warranty

FMINT25 is a performance intercooler for the Toyota Yaris GR, produced, designed, and tested at our headquarters in Gloucester UK. Throughout the development process we have strived to improve the efficiency and performance of the Yaris GR’s engine. Our project brief was to develop an intercooler utilising all of the available space available in the original position of the OEM intercooler, and to ensure the inlet air temperature is reduced, without any negative effects on the boost pressure or engine and transmission cooling.

Using a combination of scanning software and traditional measuring methods, the design was created. This was then fine tuned by our computational fluid dynamics (CFD) team, and the end tanks were initially created by 3D printers. We then alloy cast our first prototypes from our 3D prints using a sand casting technique and started the testing procedure on several types of intercooler cores.

The first iteration fitted the vehicle perfectly, however, our technicians and engineers felt the inlet and outlet should be enlarged along with providing the end user with the necessary boost pipes to ensure flow was maximized on the Toyota`s GR 3 cylinder engine.

Before getting to work on the dyno, we spec'd three different type of cores; one of these being bar and plate and two being a tube and fin construction - with all three cores having different internal and external fin pitches and configurations. We then welded the test parts ready for testing along with fabricating an internal baffle to the inlet (hot side) of the end tank. This is to ensure, from our CFD research, that the total volume of the core internal is utilised for optimum performance.

Compared to the OEM intercooler, the improved Forge product has a surface area increase of over 42% and an internal volume increase of over 100% as well as Gains of more than